New Horizons

John and Bette Hope wash away backing paper on “New Horizons” mosaic with Clara and Morgan Campbell. Drawing by Nicole Campbell

Inspired by all the possibilities and places you can go when your car is well cared for, “New Horizons” is the name of the 6 foot by 12 foot glass tile mosaic on the outside of Quick Lane.

CITY OF MOSAICS

Although Levelland has long been referred to as “The City of Mosaics,” the town officially received this title in a bill signed by Governor Abbott in 2019. The designation comes to Levelland as there are more mosaics per capita than anywhere else in Texas. “New Horizons” is the 14th mosaic and there are even more in the works. Visit the City of Levelland’s website for a self-guided tour available to see each one.

We loved the idea of adding a mosaic to the collection, and patiently waited for the right opportunity.

HOW IT STARTED

In the summer of 2020 we received early design plans for what would become Quick Lane Tire & Auto Center of Levelland. This expansion to our business was exciting in its own right, and then it occurred to us that the wall facing College Ave was the perfect spot for a mosaic! Around that time, an issue of Senior Link magazine came across my desk. On page 51 was a story about local artists, John & Bette Hope.

I highly recommend reading the article so you can fall in love with the Hopes as much as I did. Immediately, there was no one else I wanted to work with for our mosaic. I nervously gave Bette a call and was relieved not only at how excited she was for the project, but also for how warm she was from the start. We planned to meet in person to begin.

DESIGN PROCESS

We knew we wanted colors to compliment Quick Lane’s blue and orange branding, as well as a scene somehow related to cars and taking care of your vehicle. My mom, Annette, is a painter and I am a graphic designer, so our collective mosaic experience is… looking at them. This is to say, we had no idea whatsoever how they were made. So in preparation to meet with John and Bette, all I could offer was a mood board. It felt a little like handing a cut-and-pasted magazine collage to Picasso.

The Hopes examined my color and theme suggestions thoughtfully and excitedly began tossing tile color suggestions back and forth. There was still no building to reference at this time, so we looked at the architect’s plans to strategize size and positioning. At this point, we were still able to modify the wall where the mosaic would fit and added an inset portion so the mosaic could be recessed and thus, more protected from the elements.

John and Bette asked lots of questions and made certain they understood our vision for the piece, which I appreciated very much. They took those thoughts, did some sketching, collaging, and some back-and-forthing until we finally landed on “the one.” Our first look at “New Horizons” was a culmination of collage, photoshop, and paint. From there, the building process could begin.

BUILDING PROCESS

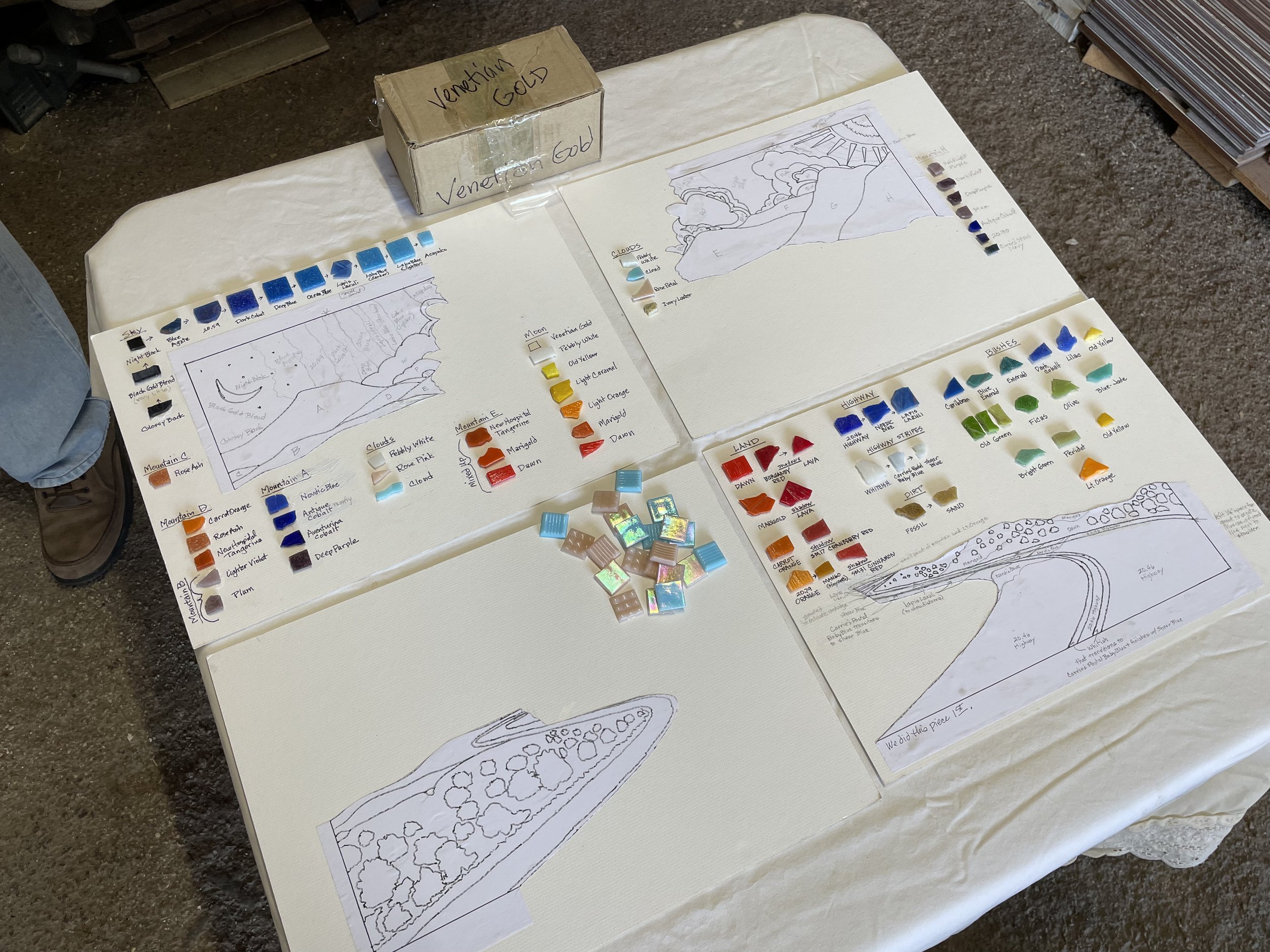

John and Bette began with tile selection. “New Horizons” is composed of glass tiles which are more durable than a ceramic alternative. Glass tiles can withstand the elements, including hail, without much if any damage. The colors also do not fade in the sun like a ceramic option would. Colors are selected, then sourced from around the world. For new tiles, this proved to be uniquely challenging during supply chain shortages. For tiles that could be used from their stock, the tedious sorting and cleaning process could begin.

As the tiles were being prepared, the design was brought to full scale by tracing a projection onto paper. A lot of this was done with the gracious help of Mosaic Coffee Co. lending the use of their large meeting space. (Thank you!) The paper would become the surface on which tiles are applied and placed in sections onto the wall. Because of this, the full scale trace had to be in mirror image of the final design. Once the tiles get applied to the wall, the paper washes off and leaves you with the final product!

John and Bette’s Quadrant Map & Color Scheme

The tile application is a long process which would have to be done in John and Bette’s studio so they could work at all hours. Due to the large 6 foot by 12 foot size, the mosaic would have to be assembled in four parts. So once the design was made full scale, John and Bette consciously divided it into sections. They carefully divided it along the natural curves of the design, instead of using a square grid which might have led to a disjointed final product. The attention to details like this amazed me, and I’m sure there are many more instances I wasn’t even aware of throughout the process. Details are the reason finding highly skilled artists are always worth it.

Tiles trimmed & laid directionally give the road a nice perspective effect.

Once divided, the tile application began! Tiles were glued to their respective places on the paper using soluble paste. The “pretty” side was applied face down so it could eventually be the side that shows. Then tile by tile, color by color, section by section, hour by hour, John and Bette pieced together a work of art.

Another instance of their attention to detail can be seen in the road part of the design. While the tiles could have simply been laid in a grid-like fashion, instead the Hopes carefully trimmed the tiles and laid them in such a way to achieve perspective. This means that instead of a “good enough” blue tile road, we ended up with a piece that feels like you could step right in and go somewhere.

Along the way, the Hopes invited many of us from Smith Auto Family and Quick Lane (big to small!) to come lay tiles so we could claim a piece of the credit. For me, this was a special experience to share with my children. I love the idea of them growing up and having a beautiful piece of public art to see and remember that they had a hand in bringing it to fruition. This is an experience I didn’t really consider; rather, it was John and Bette who knew that would be special and encouraged us to involve them.

Once assembly was complete, the mosaic was transported to Quick Lane in the large quartered sections. John and Bette used the large floor of our parts storage room to piece it together only to… slice it into pieces again. This time, smaller pieces would be sliced, again along natural curves of the design, so that the tiles could be applied to their final place on the wall. Smaller sections made this part more manageable.

After the jigsaw was complete, tiles were left to cure in the mortar and get firmly set in place. At this point, the view was the backside of the original full scale trace, along with lots of tape securing the sections in place. Then, to use Bette’s words, “like magic” the Hopes peeled off the tape, used water to wash away the paper, and finally revealed the front side of the tiles in all their glory! It was at this point I realized that the entire mosaic process has to be done without the artist ever getting a real preview of the final product. They can only see the backside of the tiles as they go. So it’s not until everything is applied to the wall and washed clean do they ever get to see the full beauty of their (1000+ hours of) work.

I can’t say enough about how glad I am that this dream of adding a mosaic to Levelland’s collection has come true. I am incredibly grateful for John and Bette Hope for their time, talents, and love. I’m grateful to my parents, Pat and Annette Sykora, who first had the idea to have a mosaic and allowed me to do all the fun parts to make it happen.

If you’re around, stop by to see “New Horizons” at 502 College Avenue in Levelland, Texas. Snap some photos and tag @quicklanelevelland!

Fellow business owners, if you are considering a beautification project of your own, I would be glad to answer any questions for you about our process. Please reach out to me at ncampbell@smithautofamily.com.